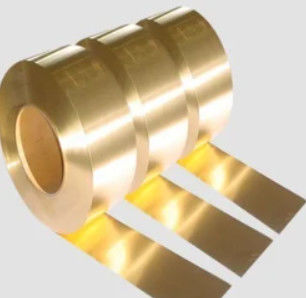

Corrosion Resistance Copper Alloy Strip Composite Material For Battery

A corrosion-resistant copper alloy strip refers to a specific type of strip made from a copper alloy that is highly resistant to corrosion. Here's a description of its key features and properties:

-

Material: The strip is primarily composed of a copper alloy that is specifically formulated to exhibit excellent corrosion resistance. Copper alloys can be blended with various elements such as nickel, tin, zinc, or aluminum to enhance their corrosion resistance properties.

-

Corrosion Resistance: The corrosion-resistant copper alloy strip is designed to withstand the effects of corrosion, which can occur due to exposure to moisture, chemicals, or other corrosive substances. The specific resistance to corrosion depends on the alloy composition and the presence of protective elements.

-

Alloy Composition: The exact composition of the copper alloy strip can vary depending on the specific application requirements. Commonly used copper alloys with corrosion resistance properties include copper-nickel alloys (e.g., C70600, C71500), phosphor bronze (e.g., C51000), and various brass alloys.

-

Durability: The corrosion-resistant copper alloy strip is known for its durability and long-term performance. It can withstand harsh environmental conditions and maintain its structural integrity, even in corrosive environments.

-

Formability: Copper alloy strips are highly formable, allowing for easy shaping and fabrication into desired forms or components. They can be bent, stamped, machined, or welded to meet specific application requirements.

-

Applications: Corrosion-resistant copper alloy strips find applications in various industries where high corrosion resistance is required. They are commonly used in electrical and electronic equipment, marine applications, plumbing systems, heat exchangers, architectural applications, and chemical processing equipment.

-

Sizes and Dimensions: Copper alloy strips are available in various sizes, thicknesses, and widths to suit different application requirements. The specific dimensions and tolerances can vary depending on the manufacturer and industry standards.

-

Surface Treatments: To further enhance the corrosion resistance of copper alloy strips, additional surface treatments may be applied. These treatments can include coatings, plating, or chemical treatments that provide an additional layer of protection against corrosion.

It's important to note that the description provided here is based on the general characteristics of corrosion-resistant copper alloy strips. The specific alloy composition, corrosion resistance properties, and application suitability may vary depending on the manufacturer, alloy type, and product specifications. Consulting with manufacturers or suppliers who specialize in corrosion-resistant copper alloy strips is recommended to obtain accurate and detailed information based on specific requirements.

Characteristics of pure copper

Pure copper is a rose red metal, the surface of the formation of copper oxide film is purple, so industrial pure copper is often called copper or electrolytic copper. Fire smelting can obtain 99-99.9% pure copper, electrolysis can make the purity of copper to 99.95-99.99%. It has a density of 8-9g/cm3 and a melting point of 1083°C. Pure copper conductivity is very good, a large number of used in the manufacture of wire, cable, brush and so on; Good thermal conductivity, commonly used to manufacture magnetic instruments, instruments, such as compasses, aviation instruments, etc. Excellent plasticity, easy to hot press and cold pressure processing, can be made into tubes, rods, wires, strips, belts, plates, foils and other copper materials. Pure copper products have two kinds of smelting products and processed products. Product specifications are complete, the price is favorable, the packaging is intact, the copper is pure, the straightness is good, the inventory is large, can provide material certification and SGS report.

character:Good electrical conductivity. Corrosion resistance and processability, can be welded and fiber welding. Contains less impurities that reduce electrical conductivity, and a trace amount of oxygen is conductive to electricity. Thermal conductivity and processing properties have little impact, but it is easy to cause "hydrogen disease", and it is not suitable for processing (annealing) in a reducing atmosphere at high temperatures (such as >370°). Welding, etc.) and use

Copper parameter

chemical composition

| material |

C11000 |

| chemical composition |

Bi% |

Sb% |

As% |

Fe% |

Pb% |

S% |

Cu+Ag% |

| 0.001 |

0.002 |

0.002 |

0.005 |

0.005 |

0.005 |

99.90 |

mechanical properties

| mechanical properties |

Yield Strength |

tensile strength |

elongation |

| ≥295 |

≧65 |

≧3 |

Our advantage

| FLEXIBILITY |

MISSION |

QUALITY |

SERVICE |

STABILITY |

| MOQ only 200KG, Sheet/Coil |

Being your trusted steel expert |

100% quality guarantee, supporting the third-party inspection |

Fast Response, Fast shipping & Fast delivery Well-appointed machining equipments, Own logistics |

Long-term & stable material Inventory, Wide variety of material types & specifications |

Product Inventory

Jiangsu Jinruiheng uses standard export transportation packaging, according to the size of the stainless steel plate binding steel belt. According to our shipping experience, a 20-foot container can hold 22 tons of stainless steel, and a 40-foot container can hold 25 tons of stainless steel. For larger orders, we ship by bulk carrier, which is cheaper. Packaging can also be customized according to customer needs.

Packing and Shipping:

DELIVERY SERVICE COMMITMENT:

The goods shall be delivered in strict accordance with the contract, and the consignee shall be notified within 48 hours after thegoods are delvered: Loading shall be carried out in strict accordance with the requlations. without overloading, bias and weiahtgathering

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!