Material:

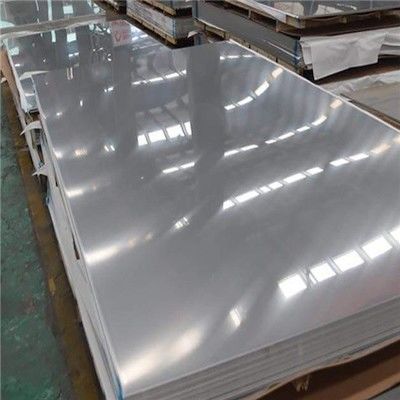

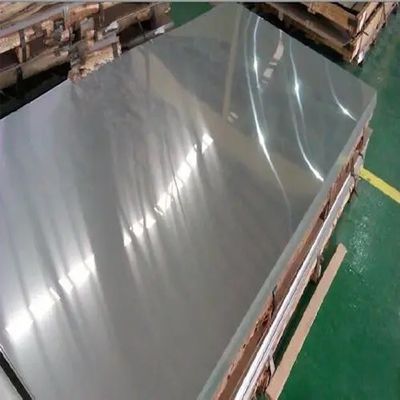

304 Stainless Steel

Grade:

304 (Austenitic)

Thickness:

3mm

Dimensions:

Customizable (length And Width As Per Customer Requirements)

Strength:

High Tensile And Yield Strength, Providing Durability In Demanding Applications

Weldability:

Excellent, Can Be Easily Welded Using Common Techniques

Formability:

Good, Suitable For Bending, Cutting, And Shaping

Package:

Standard Packing

Temperature Resistance:

Up To 870°C In Continuous Service And 925°C In Intermittent Service

Price Term:

EXW, Fob, CFR, CIF, Etc.

Applications:

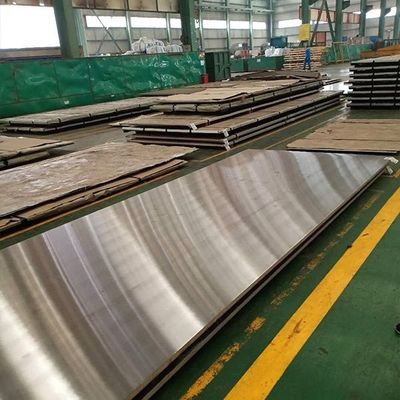

Used In Industrial Sectors Like Chemical Processing, Food Processing, Water Treatment, And Construction

Invoicing:

By Theoretical Weight

Certification:

Meets ASTM A240, EN 10088-2 Standards

Production Capacity:

30000 Tons Per Month

Special Features:

Non-magnetic In Annealed Condition, Recyclable, And Environmentally Friendly

Origin:

Jiangsu, China

Product Type:

Metal Plates

Heat Resistance:

High

Highlight:

3mm Thickness Stainless Steel Sheet

, Industrial Corrosion Resistant Stainless Steel Sheet

, 304 Grade Stainless Steel Sheet

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!