AISI EN 304L stainless steel sheet metal Stainless Steel plate

304L Stainless steel Sheet description

A 304L stainless steel sheet is a low-carbon variation of the 304 stainless steel grade. It offers similar corrosion resistance and mechanical properties as 304 stainless steel, but with improved weldability. Here is a description of a 304L stainless steel sheet:

-

Composition: 304L stainless steel is an austenitic stainless steel alloy, which primarily consists of iron, chromium (18-20%), and nickel (8-12%). The low carbon content (typically around 0.03% or lower) in 304L stainless steel helps to minimize carbide precipitation during welding, reducing the risk of sensitization and intergranular corrosion.

-

Corrosion resistance: 304L stainless steel exhibits excellent corrosion resistance, similar to 304 stainless steel. It is resistant to corrosion from various environments, including atmospheric conditions, fresh water, mild acids, and alkaline solutions. However, it may be susceptible to corrosion in highly corrosive environments such as marine environments or exposure to certain chemicals.

-

Weldability: The low carbon content in 304L stainless steel provides improved weldability compared to standard 304 stainless steel. It reduces the risk of sensitization, which can lead to intergranular corrosion in the heat-affected zone during welding. 304L stainless steel can be readily welded using common welding methods, including TIG (tungsten inert gas) and MIG (metal inert gas) welding techniques.

-

Strength and durability: 304L stainless steel has similar mechanical properties to 304 stainless steel. It offers good tensile strength, moderate to high levels of mechanical stress resistance, and good toughness. The alloy is suitable for a wide range of applications that require strength and durability.

-

Formability and versatility: 304L stainless steel is highly formable, making it suitable for various fabrication processes such as bending, rolling, and deep drawing. It can be easily formed into different shapes and sizes to meet specific project requirements. The versatility of 304L stainless steel makes it suitable for a wide range of applications.

-

Applications: 304L stainless steel sheets find applications in industries such as:

- Food processing and storage equipment

- Chemical processing equipment

- Pharmaceutical equipment

- Heat exchangers and boilers

- Architectural and decorative applications

- Automotive components

- Plumbing and sanitary systems

- Petrochemical industry

-

Availability: 304L stainless steel sheets are available in various thicknesses, widths, and lengths. They can be supplied with different surface finishes, including mill finish, brushed finish, or polished finish.

It's important to note that the specific properties, availability, and standards for 304L stainless steel sheets may vary depending on the supplier and the specific manufacturing process. It is advisable to consult with the supplier or review the relevant specifications to ensure the desired properties and specifications are met for your specific application.

304L Stainless steel Sheet parameter

chemical composition

| material |

201 |

| chemical composition |

C% |

Cr% |

Ni% |

Mn% |

Si% |

N% |

P% |

S% |

| ≦0.15 |

16.0-18.0 |

3.5-5.5 |

5.50-7.50 |

≦1.00 |

≦0.25 |

≦0.060 |

≦0.030 |

mechanical properties

| mechanical properties |

Yield Strength |

tensile strength |

elongation |

Hardness |

| ≧45 |

≧95 |

≧40 |

≦100 |

Unique properties of 304L stainless steel

304L stainless steel is a popular material that possesses unique and impressive properties. One of its most notable features is its exceptional corrosion resistance, which makes it resistant to rust and other forms of deterioration caused by environmental factors. It is also highly resistant to heat and oxidation, making it suitable for use in high-temperature environments.

Additionally, 304L stainless steel has excellent machinability properties, allowing it to be easily shaped into various forms without losing its structural strength. Its superior toughness and ductility make it an ideal choice for manufacturing equipment that requires durability and reliability.

Another characteristic of 304L stainless steel is its low magnetic permeability, which makes it useful in applications where magnetic interference must be avoided. This property enables the material to resist magnetization when subjected to intense electromagnetic fields or radiation.

Due to its cost-effectiveness compared with other types of alloys used in similar applications, 304L stainless steel offers manufacturers significant savings while providing desirable mechanical properties.

These unique properties make 304L stainless steel an attractive option for various industrial applications such as automotive parts manufacturing, kitchen equipment production, construction materials fabrication among others.

What shapes can 304L stainless steel be made into?

304L stainless steel can be formed into different grades of stainless steel plate using various methods. The most common method is to use a press brake with appropriate dies to form the desired shape. Other methods include using dies, stamping or hydroforming.

304 stainless steel stainless steel sheet can be made into many different shapes,

We can make a suitable shape according to your needs.

Why choose 304L stainless steel?

When it comes to selecting the right material for your project, there are a plethora of options available. However, 304L stainless steel has become an increasingly popular choice amongst many industries in recent years. Here’s why.

Its excellent corrosion resistance properties make it suitable for use in harsh environments such as marine and chemical applications. This is due to the addition of manganese which enhances its overall performance.

Secondly, 304L stainless steel exhibits exceptional wear and tear resistance making it ideal for products that require high durability such as kitchen appliances and automotive parts.

This type of steel has good heat resistance properties and can withstand temperatures up to 870°C without losing strength or becoming brittle.

Fourthly, unlike other types of stainless steel that contain nickel which can cause allergic reactions in some people, 304L stainless steel is nickel-free making it a safer option for those with sensitive skin.

Compared to other grades of stainless steel like 304L or 316L, 304L stainless steel is more cost-effective while still providing similar benefits making it an attractive option from both economic and performance perspectives.

Surface Finish

Stainless steel not only has corrosion resistance, but also has the advantages of heat resistance, processability, strength, appearance and so on. Stainless steel manufacturers take advantage of the properties of stainless steel to improve quality through various surface treatments. Jin Ruiheng Stainless Steel offers BA, 2B, 2D, 2K, 4K, 6K, 8K, NO.4, HL, SB, Embossed and other different types of stainless steel surface treatment processes.

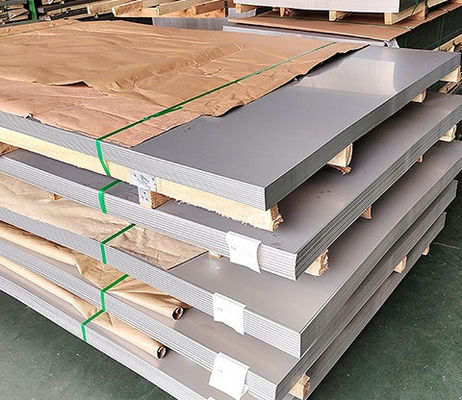

Packing and Shipping:

DELIVERY SERVICE COMMITMENT:

The goods shall be delivered in strict accordance with the contract, and the consignee shall be notified within 48 hours after thegoods are delvered: Loading shall be carried out in strict accordance with the requlations. without overloading, bias and weiahtgathering

Our advantage

| FLEXIBILITY |

MISSION |

QUALITY |

SERVICE |

STABILITY |

| MOQ only 200KG, Sheet/Coil |

Being your trusted steel expert |

100% quality guarantee, supporting the third-party inspection |

Fast Response, Fast shipping & Fast delivery Well-appointed machining equipments, Own logistics |

Long-term & stable material Inventory, Wide variety of material types & specifications

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!