16Mn Carbon Steel Coil ANSI Cold Reduced Carbon Steel Strapping Hr Coil Sheet

16Mn is a low alloy high-strength structural steel commonly used in China. When referring to 16Mn carbon steel coil, it means that the steel is in the form of a coil and meets the requirements specified for 16Mn carbon steel. Here is a description of 16Mn carbon steel coil:

-

Composition: 16Mn carbon steel coil is primarily composed of iron and carbon, with additional alloying elements such as manganese (0.90-1.20%), silicon (0.20-0.55%), and trace amounts of phosphorus, sulfur, and other alloying elements. The alloying elements contribute to the steel's higher strength and improved mechanical properties.

-

Strength and ductility: 16Mn carbon steel coil exhibits higher strength compared to standard carbon steels. It has a minimum yield strength of 345 MPa (megapascals) and a minimum tensile strength of 470 to 660 MPa, depending on the thickness. The higher strength makes it suitable for structural applications that require greater load-bearing capacity.

-

Formability: The coil form of 16Mn carbon steel allows for easy processing and fabrication. It can be cut, bent, and shaped into different forms without sacrificing its structural integrity. This makes it suitable for applications that require complex shapes, such as structural components, machinery, and equipment.

-

Weldability: 16Mn carbon steel coil has good weldability when appropriate welding procedures are followed. It can be welded using common welding methods such as arc welding, MIG (metal inert gas) welding, and TIG (tungsten inert gas) welding. However, preheating and post-weld heat treatment may be required for thick sections or critical applications to minimize the risk of weld cracking.

-

Corrosion resistance: 16Mn carbon steel is not inherently corrosion resistant and may require additional protective coatings or treatments to prevent rust and corrosion. It is important to note that the corrosion resistance of 16Mn steel will depend on the environment and the specific protective measures applied.

-

Applications: 16Mn carbon steel coil finds applications in various industries, including:

- Structural components in buildings, bridges, and infrastructure

- Machinery and equipment manufacturing

- Construction machinery

- Pressure vessels and boilers

- Automotive components

- Oil and gas pipelines

- Mining equipment

Please note that the specific properties and availability of 16Mn carbon steel coil may vary depending on the manufacturer and the specific manufacturing process. It is recommended to consult with the supplier or review the relevant specifications to ensure the desired properties and specifications are met for your specific application.

Application of carbon steel Coil

Carbon steel is a popular material in the manufacturing industry. It’s strong, reliable and incredibly versatile. When it comes to finding the right carbon steel for your application, you have many options to choose from – each with different properties. carbon steel is one of the most widely used options available on the market today. This type of carbon steel has specific qualities that make it ideal for certain applications. In this blog post, we’ll explore the application of carbon steel and how it can benefit your business.

Performance of carbon steel Coil

The performance of Carbon steel coil depends on its chemical composition, microstructure, and processing method. The material is known for its excellent strength, high dimensional accuracy, and good surface quality. It is also resistant to fatigue and has good weldability.

In terms of mechanical properties, Carbon steel coil has a tensile strength of 440 MPa, a yield strength of 305 MPa, and an elongation of 31%. These properties make it suitable for use in automobile parts that require high strength and good formability, such as wheels, chassis, and suspension systems.

Overall, Q195 Carbon steel coil is a high-quality steel material that is widely used in the automobile industry due to its excellent performance and reliability.

Carbon Steel Coil parameter

chemical composition

| material |

|

| chemical composition |

C% |

Ni% |

Mn% |

P% |

S% |

| 0.12 |

3.5-5.5 |

0.5 |

0.35 |

0.04 |

mechanical properties

| mechanical properties |

Yield Strength |

tensile strength |

elongation |

Hardness |

| ≧45 |

≧95 |

≧40 |

≦100 |

Our advantage

| FLEXIBILITY |

MISSION |

QUALITY |

SERVICE |

STABILITY |

| MOQ only 200KG, Sheet/Coil |

Being your trusted steel expert |

100% quality guarantee, supporting the third-party inspection |

Fast Response, Fast shipping & Fast delivery Well-appointed machining equipments, Own logistics |

Long-term & stable material Inventory, Wide variety of material types & specifications |

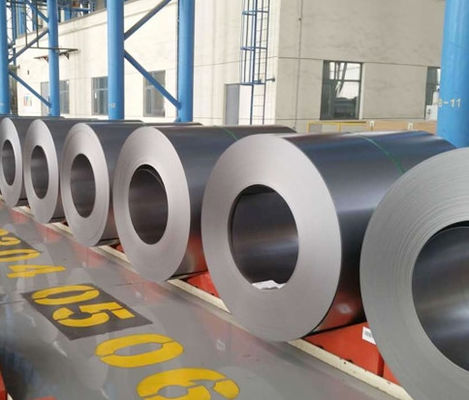

Product Inventory

Jiangsu Jinruiheng uses standard export transportation packaging, according to the size of the stainless steel plate binding steel belt. According to our shipping experience, a 20-foot container can hold 22 tons of stainless steel, and a 40-foot container can hold 25 tons of stainless steel. For larger orders, we ship by bulk carrier, which is cheaper. Packaging can also be customized according to customer needs.

Packing and Shipping:

DELIVERY SERVICE COMMITMENT:

The goods shall be delivered in strict accordance with the contract, and the consignee shall be notified within 48 hours after thegoods are delvered: Loading shall be carried out in strict accordance with the requlations. without overloading, bias and weiahtgathering

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!