High Strength 316 Stainless Steel Plate 2mm Thickness for Marine Equipment

Technical Parameters:

| Parameter |

Value |

| Strength |

High |

| Material |

Stainless Steel |

| Industry |

Medical |

| Corrosion Resistance |

High |

| Standard |

ASTM |

| Product Type |

Metal Plates |

| Durability |

Long-lasting |

| Length |

Customized |

| Size |

2 mm or Customized |

| Application |

Medical equipment and devices |

| Product Name |

316 Stainless Steel Plates |

| Material Grade |

316 |

| Plate Type |

316 SS Plate |

| Plate Size |

Customized |

| Welding Method |

TIG welding |

| Plate Thickness |

Customized |

| Plate Surface |

Polished |

Introduction

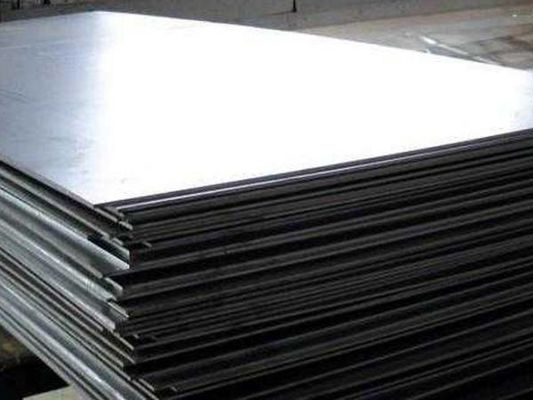

The High Strength 316 Stainless Steel Plate with a 2mm thickness is designed to meet the demanding requirements of marine environments. This product combines the exceptional properties of 316 stainless steel with a precise thickness to deliver superior performance and reliability. Ideal for use in marine equipment, this stainless steel plate offers a range of benefits that make it a preferred choice for professionals in the maritime industry.

Material Composition

316 stainless steel is a high-grade alloy that contains chromium, nickel, and molybdenum. The specific composition includes:

- Chromium (16-18%): Provides excellent corrosion resistance and enhances the steel's hardness.

- Nickel (10-14%): Improves the steel's toughness and resistance to oxidation.

- Molybdenum (2-3%): Enhances resistance to pitting and crevice corrosion, particularly in chloride-rich environments.

This unique composition ensures that the 316 stainless steel plate offers superior durability and performance in harsh marine conditions.

Key Properties

- Corrosion Resistance: One of the standout features of 316 stainless steel is its exceptional resistance to corrosion. The addition of molybdenum significantly improves its ability to withstand chloride-induced corrosion, making it ideal for marine applications where exposure to seawater and salt spray is common.

- High Strength: The plate’s high-strength properties make it suitable for structural applications and components that require robustness and durability. Its tensile strength and resistance to deformation ensure that it can withstand mechanical stresses and impacts.

- Temperature Resistance: 316 stainless steel performs well in a wide range of temperatures. It maintains its mechanical properties and dimensional stability even at elevated temperatures, making it suitable for use in environments with fluctuating temperatures.

- Formability and Weldability: Despite its strength, 316 stainless steel is relatively easy to form and weld. This characteristic is advantageous for fabricating complex shapes and structures required in marine equipment.

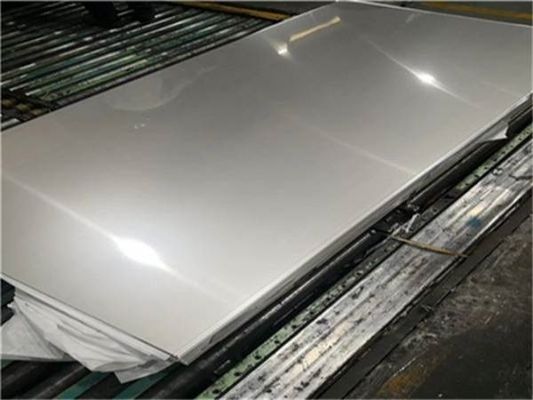

- Aesthetic Appeal: The smooth and polished surface of the 316 stainless steel plate adds to its aesthetic appeal, making it suitable for applications where appearance is important, such as decorative elements on marine vessels.

-

Specifications

- Thickness: 2mm

- Width and Length: Customizable based on client requirements.

- Finish: Can be supplied in various finishes, including polished, matte, or brushed, depending on application needs.

- Standards Compliance: Conforms to international standards such as ASTM A240, EN 10088, and JIS G4304.

Applications

The High Strength 316 Stainless Steel Plate is extensively used in marine and maritime applications, including:

- Marine Equipment: Ideal for manufacturing components such as hulls, decks, and superstructures of ships and boats.

- Marine Hardware: Used in the production of fittings, fasteners, and other hardware exposed to seawater.

- Offshore Platforms: Suitable for parts of offshore rigs and platforms that need to withstand harsh environmental conditions.

- Corrosion-Resistant Panels: Used in the construction of panels and coverings in coastal and marine environments.

Advantages

- Durability: The high strength and corrosion resistance ensure a long service life and reduced maintenance requirements, translating into cost savings over time.

- Reliability: The plate's consistent quality and performance provide reliability in critical marine applications where failure is not an option.

- Versatility: Its formability and weldability make it adaptable for various manufacturing processes and design requirements.

- Safety: The plate's resistance to corrosion and oxidation contributes to the safety and integrity of marine structures and equipment.

Manufacturing Process

The production of High Strength 316 Stainless Steel Plates involves several key steps:

- Melting: Raw materials are melted in an electric arc furnace to form molten steel.

- Casting: The molten steel is cast into semi-finished products such as slabs.

- Hot Rolling: The slabs are hot-rolled to the desired thickness, followed by cooling and annealing to enhance properties.

- Cold Rolling: Further processing through cold rolling mills achieves the final thickness and surface finish.

- Quality Control: Rigorous testing and inspection ensure that the plates meet the required specifications and standards.

Quality Assurance

Our 316 stainless steel plates undergo stringent quality control procedures to ensure they meet the highest standards. Key quality assurance measures include:

- Chemical Composition Analysis: Verifying that the alloying elements meet the specified levels.

- Mechanical Testing: Assessing tensile strength, yield strength, and elongation to ensure mechanical properties.

- Corrosion Testing: Evaluating resistance to corrosion in simulated marine environments.

- Dimensional Inspection: Ensuring the plate dimensions and thickness are within specified tolerances.

Environmental Considerations

Our manufacturing processes adhere to environmental regulations to minimize the impact on the environment. We employ energy-efficient practices, recycle materials, and manage waste responsibly.

Packaging and Delivery

The High Strength 316 Stainless Steel Plates are carefully packaged to prevent damage during transit. Packaging options include protective wrapping and crating as needed. Delivery schedules are tailored to meet client requirements, with options for expedited shipping if required.

Conclusion

The High Strength 316 Stainless Steel Plate with a 2mm thickness is an excellent choice for marine equipment and applications where durability, corrosion resistance, and high strength are essential. Its superior properties make it a reliable and cost-effective solution for professionals in the maritime industry. For more information or to request a quotation, please contact us.

Packing and Shipping:

Packaging and Shipping

Packaging

The Stainless Steel Metal Plates are carefully packaged to ensure safe delivery to our customers. The packaging process includes the following steps:

- Each plate is wrapped in a protective layer to prevent scratching or damage during transport.

- The wrapped plates are then placed in a sturdy cardboard box.

- The box is filled with cushioning material to provide extra protection.

- The box is sealed with strong adhesive tape to secure the contents.

Shipping

We offer various shipping methods to meet the specific needs of our customers. The available shipping options include:

- Standard Shipping: This is our most economical option and usually takes 3-5 business days for delivery.

- Express Shipping: For customers who need their order urgently, we offer express shipping which takes 2-3 business days for delivery.

- International Shipping: We ship our products worldwide and offer competitive rates for international shipping.

Once your order has been shipped, we will provide you with a tracking number so you can keep track of your package during transit.

Please note that shipping times may vary depending on the destination and any potential customs delays. We will do our best to ensure your order is delivered in a timely manner.

If you have any special shipping requests, please contact us and we will do our best to accommodate your needs.

FAQ:

.

Q1: What makes 316L stainless steel ideal for food processing?

A1: 316L stainless steel is renowned for its superior corrosion resistance, high durability, and ease of cleaning, making it ideal for maintaining hygiene standards in food processing environments.

Q2: How does the 1.3mm thickness benefit my applications?

A2: The 1.3mm thickness provides a perfect balance of strength and flexibility, making the plate robust enough for demanding applications while still being easy to work with and install.

Q3: What is the advantage of a polished finish?

A3: The polished finish not only enhances the visual appeal of the stainless steel plate but also makes it easier to clean and maintain, which is essential for food processing applications where hygiene is critical.

Q4: Can this stainless steel plate withstand high temperatures?

A4: Yes, our 316L stainless steel plate is designed to tolerate extreme temperatures, making it suitable for use in both high-heat environments like ovens and low-temperature settings such as refrigeration units.

Q5: Is the 316L stainless steel plate non-reactive with food?

A5: Absolutely. 316L stainless steel is non-reactive, meaning it will not impart any flavors or contaminants to food, ensuring product safety and quality.

Q6: How can I get a quote or place an order?

A6: To get a quote or place an order, please contact us directly at (Jessie@jrhss.com). Our team is ready to assist you with your specific needs and provide you with competitive pricing options.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!