GB/T 2518 Galvanized Steel Sheet Cold Rolled Hot Dipped G550

GB/T 2518 is a Chinese national standard that specifies the requirements for galvanized steel sheets produced through the cold-rolled process. Here is a description of GB/T 2518 galvanized steel sheet (cold-rolled):

-

Composition: The base material for GB/T 2518 galvanized steel sheets is typically low-carbon steel or mild steel. The specific composition may include elements such as carbon, manganese, phosphorus, sulfur, and silicon. The low carbon content ensures good weldability and formability.

-

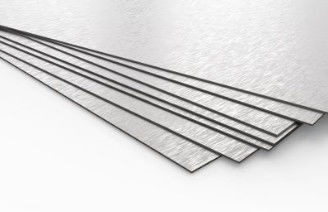

Cold-Rolling Process: The steel sheet undergoes a cold-rolling process, where it is passed through a series of rollers at room temperature to reduce its thickness and improve its surface finish. Cold-rolling provides tighter dimensional tolerances and enhances the mechanical properties of the steel.

-

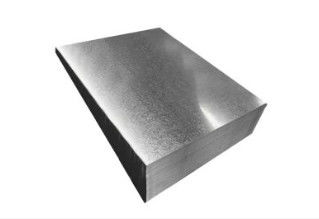

Galvanization Process: After cold-rolling, the steel sheet is further processed through a galvanizing process to apply a protective zinc coating. The galvanization process may involve either a hot-dip or electroplating method, where the steel sheet is coated with a layer of zinc to provide corrosion resistance.

-

Zinc Coating: The zinc coating applied to the cold-rolled galvanized steel sheet provides excellent corrosion resistance. The thickness of the zinc coating can vary depending on the application and customer specifications. The coating weight is typically specified in terms of the mass of zinc per unit area, such as grams per square meter (g/m²) or ounces per square foot (oz/ft²).

-

Size and Thickness: GB/T 2518 galvanized steel sheets are available in various sizes and thicknesses. Common sizes include 4x8 feet sheets or coils. The thickness can vary depending on the application and customer requirements.

-

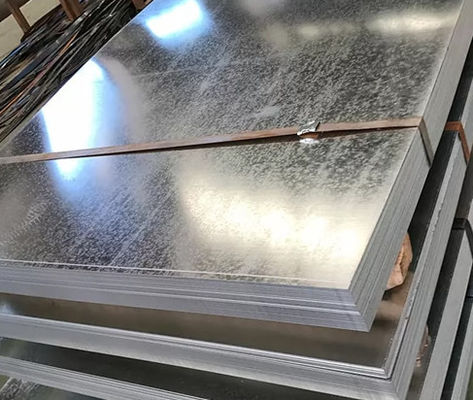

Surface Finish: The galvanized steel sheet produced through the cold-rolled process typically has a smooth and uniform surface finish. The surface is free from scale, rust, and other imperfections, providing an aesthetically pleasing appearance.

-

Applications: GB/T 2518 galvanized steel sheets find applications in various industries and applications, including but not limited to:

- Construction of roofing, cladding, and siding for buildings

- Manufacturing of appliances, such as refrigerators and ovens

- Automotive components and body panels

- Electrical enclosures and cabinets

- HVAC systems and ductwork

- General fabrication and manufacturing

GB/T 2518 galvanized steel sheets produced through the cold-rolled process offer good dimensional accuracy, surface quality, and corrosion resistance, making them suitable for a wide range of applications.

It is important to note that the specific properties and availability of GB/T 2518 galvanized steel sheets may vary depending on the manufacturer and region. It is recommended to consult with suppliers and review the product specifications to ensure the desired properties and specifications are met for your specific application.

The benefits of using professional hot-dip galvanized sheet

When it comes to ductwork for air conditioning and ventilation systems, there are a lot of materials that can be used. But if you want something that is going to last and perform well, hot-dip galvanized sheet is the way to go. Galvanized steel has a coating of zinc that protects it from corrosion, making it ideal for use in ductwork that will be exposed to moisture or other corrosive elements.

Hot-dip galvanized sheet also has a number of other benefits:

It’s durable: Hot-dip galvanized steel is incredibly durable, meaning it won’t corrode or degrade over time like other materials can. This makes it ideal for use in ductwork that will be subject to high temperatures or harsh conditions.

It’s fire resistant: Galvanized steel is non-combustible, making it an excellent choice for use in ductwork near heat sources or in buildings where fire safety is a concern.

It’s easy to work with: Galvanized steel is relatively easy to cut, bend, and weld, making it a good choice for DIY projects or for use in custom applications.

It’s affordable: Hot-dip galvanized steel is one of the most affordable options for ductwork material, making it a great choice if you’re working with a limited budget.

How to properly install hot-dip galvanized sheet

When it comes to hot-dip galvanized sheet, the key is in the preparation. If the surface isn’t properly cleaned and treated, the zinc won’t adhere correctly and the finish will be compromised. That’s why it’s important to follow these steps when installing hot-dip galvanized sheet:

1. Clean the surface with a mild detergent or solvent. This will remove any grease, oil or other contaminants that could prevent the zinc from adhering properly.

2. Rinse thoroughly with clean water to remove any residue.

3. etch the surface with a weak acid solution. This will create a rougher surface for the zinc to adhere to.

4. Rinse again with clean water and dry completely.

5. Apply a primer designed for use with galvanized metal. This will help ensure a strong bond between the zinc and the metal surface.

6. Follow the instructions on the primer packaging for proper application and drying times.

7. Once the primer is dry, apply hot-dip galvanizing according to manufacturer’s instructions. Depending on the size and thickness of your sheets, this may be done by dipping them into a vat of molten zinc or by applying a zinc-rich paint onto the surface .

8 Allow ample time for the galvanizing to cure before handling or installing your sheets

Our advantage

| FLEXIBILITY |

MISSION |

QUALITY |

SERVICE |

STABILITY |

| MOQ only 200KG, Sheet/Coil |

Being your trusted steel expert |

100% quality guarantee, supporting the third-party inspection |

Fast Response, Fast shipping & Fast delivery Well-appointed machining equipments, Own logistics |

Long-term & stable material Inventory, Wide variety of material types & specifications |

Product Inventory

Jiangsu Jinruiheng uses standard export transportation packaging, according to the size of the stainless steel plate binding steel belt. According to our shipping experience, a 20-foot container can hold 22 tons of stainless steel, and a 40-foot container can hold 25 tons of stainless steel. For larger orders, we ship by bulk carrier, which is cheaper. Packaging can also be customized according to customer needs.

Packing and Shipping:

DELIVERY SERVICE COMMITMENT:

The goods shall be delivered in strict accordance with the contract, and the consignee shall be notified within 48 hours after thegoods are delvered: Loading shall be carried out in strict accordance with the requlations. without overloading, bias and weiahtgathering

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!